PET DIE-CUT LIDS

INTRODUCTION

Pre-cut plastic lids made of PET are a popular alternative to aluminium lids. The print quality achievable is higher because the plastic surface is white allowing improved graphic quality and colour definition. When transparent or clear PET with a heat-seal lacquer is used, the consumer can easily visualise the packaged product making it a highly versatile material. Metallised polyester (MET-PET) gives the lid a metallic surface and improved barrier properties.

Pre-cut plastic lids made of PET are a popular alternative to aluminium lids. The print quality achievable is higher because the plastic surface is white allowing improved graphic quality and colour definition. When transparent or clear PET with a heat-seal lacquer is used, the consumer can easily visualise the packaged product making it a highly versatile material. Metallised polyester (MET-PET) gives the lid a metallic surface and improved barrier properties.

|

PET lids are less costly to transport, they travel better and do not tear when peeled. Their high puncture resistance reduces the risk of leakers and product return. Plastic die-cut lids also allow the use of "end of line" metal detection, vital in food production and testing.

A list of some of the most common PET lid material we offer can be found below. |

Film Name |

The Substrates That The Film Seals To |

Peel Type |

Features |

Q-Lid V |

PS, PP, PE, PET, PVC, PLA |

Easy Peel |

General purpose die-cut web film. |

Q-Lid 75PET/50HT |

PP, HDPE, PE |

Strong Peel |

Suitable for retort process. |

Q-Lid Combi |

PS, PP, PE |

Strong Peel |

General purpose die-cut web film. |

Q-Lid Co-Ex |

PP, PE, HDPE, Glass, PVC, PS |

Very Strong Peel |

Used in critical applications where a very strong peel is required. |

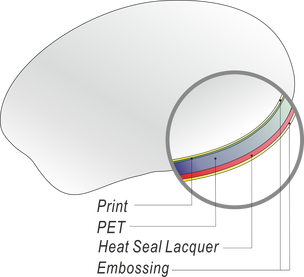

Q-LID V

Q-Lid V is a peelable heat-seal film that has been designed specifically for pre-cut lid use within the food and cosmetics sector. It can be manufactured with an anti-static coating to reduce de-nesting issues where the lids stick together.

It seals extremely well to PS, PP, PET, PE, PE lined paper and aluminium forming a strong, smooth peelable bond. It will also seal to PVC and is suitable for being placed in a microwave oven, convention all oven and refrigerated.

Q-Lid V has strong resistance to alcohol, vinegar and is capable of sealing through contaminated pots containing vegetable oils due to its hot-tack characteristics.

It seals extremely well to PS, PP, PET, PE, PE lined paper and aluminium forming a strong, smooth peelable bond. It will also seal to PVC and is suitable for being placed in a microwave oven, convention all oven and refrigerated.

Q-Lid V has strong resistance to alcohol, vinegar and is capable of sealing through contaminated pots containing vegetable oils due to its hot-tack characteristics.

|

DESCRIPION:

APPLICATION: Yoghurt, cream, cheese, deserts, salads, ready meals, instant soups, snacks, etc. |

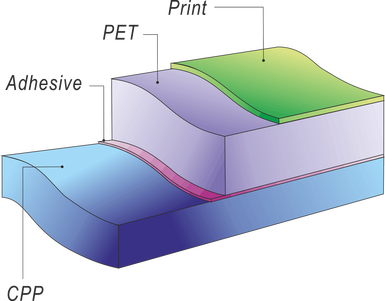

Q-Lid 75PET/50HT

Q-Lid 75/50 HT is a special laminate of 75μm PET to a special grade of 50μm CPP. This laminate is formulated to have a very strong peel seal to PP and HDPE containers. This material is steamable, pasteurisable and sterilisable. This laminate will absorb significant abuse from production processes yet will seal through contamination.

|

DESCRIPION:

APPLICATION: Yoghurt, cream, cheese, desserts, salads, ready meals, sterilised or pasteurised products, etc. |

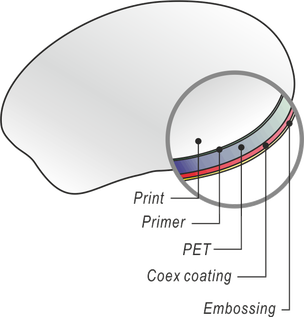

Q-LID COMBI

Q-Lid Combi seals to PP, PE, and PS Cups. It is exterior lacquered with a printing primer for improved ink adhesion. This foil is used as lidding foil for blow-moulded or injection moulded cups and containers. It provides a sterile closure in an aseptic filling process. The film is a medium peel and is tamper evident.

Q-Lid Combi can be used in applications that require hot-fill to 50°C and protects well against humidity and micro-organism attack. Optimum seal depends on sealing pressure, time, temperature and container type.

Q-Lid Combi can be used in applications that require hot-fill to 50°C and protects well against humidity and micro-organism attack. Optimum seal depends on sealing pressure, time, temperature and container type.

DESCRIPION:

APPLICATION:

Yoghurt, cream, cheese, desserts, fruit juices, snacks, instant soup, salads, etc.

- 50μm PET with heat seal lacquer

- Good moisture, gas and aroma barrier

- Good mechanical resistance against puncturing and tearing

APPLICATION:

Yoghurt, cream, cheese, desserts, fruit juices, snacks, instant soup, salads, etc.

Q-Lid PET CO-EX

INTRODUCTION

Q-Lid Co-Ex lids has a layer of extruded polypropylene that heat-seals to PE & PP containers. Since extrusion coated materials do not use solvents in the heat-seal layer, they can be considered more environmentally friendly than heat-seal lacquered material.

A key advantage of Co-Ex is that they seal within a broad temperature range and do not require as precise temperature control of the heat-seal heads. Seal strengths achieved are extremely strong, a valuable attribute where the finished product may travel at altitude before reaching the consumer.

Where a product requires a long shelf life or is pasteurised or sterilized, Co-Ex PET lids are an ideal solution. Other advantages include the elimination of container warping or panelling when packing hot-fill products.

PET lids with a thick layer of extruded polypropylene lacquer are used for sealing cups containing products which, due to their life cycle, must be pasteurised. Alternatively Q-Lid Co-Ex PET lids are used in situations where an extremely strong seal is required or where the packaged product has a high fat content or contains spices.

Q-Lid Co-Ex has been designed specifically for general purpose use. It seals extremely well to PP, PE, PE lined paper and aluminium forming a strong, smooth peelable bond. It will also seal to glass, PS and PVC and is chillable and ovenable. Q-Lid 50 PET Co-ex has strong resistance to the effects of freezing and is capable of sealing through contaminated pots containing vegetable oils due to its hot-tack characteristics. The printed side is treated with co-polyester for outstanding ink adhesion.

Q-Lid Co-Ex lids has a layer of extruded polypropylene that heat-seals to PE & PP containers. Since extrusion coated materials do not use solvents in the heat-seal layer, they can be considered more environmentally friendly than heat-seal lacquered material.

A key advantage of Co-Ex is that they seal within a broad temperature range and do not require as precise temperature control of the heat-seal heads. Seal strengths achieved are extremely strong, a valuable attribute where the finished product may travel at altitude before reaching the consumer.

Where a product requires a long shelf life or is pasteurised or sterilized, Co-Ex PET lids are an ideal solution. Other advantages include the elimination of container warping or panelling when packing hot-fill products.

PET lids with a thick layer of extruded polypropylene lacquer are used for sealing cups containing products which, due to their life cycle, must be pasteurised. Alternatively Q-Lid Co-Ex PET lids are used in situations where an extremely strong seal is required or where the packaged product has a high fat content or contains spices.

Q-Lid Co-Ex has been designed specifically for general purpose use. It seals extremely well to PP, PE, PE lined paper and aluminium forming a strong, smooth peelable bond. It will also seal to glass, PS and PVC and is chillable and ovenable. Q-Lid 50 PET Co-ex has strong resistance to the effects of freezing and is capable of sealing through contaminated pots containing vegetable oils due to its hot-tack characteristics. The printed side is treated with co-polyester for outstanding ink adhesion.

|

DESCRIPTION:

APPLICATION: Pates, pet food, canned food, spices, sauces, etc. |